Powered Ride-On ATVs for Kids | ATVs Manufacturer & Supplier

The Evolving Landscape of Powered Ride-On Toys for Kids

The market for children's recreational vehicles has witnessed significant innovation, particularly in the segment of powered ride-on toys. As a leading powered ride-on toys for kids - atvs manufacturer, we understand the critical balance between safety, durability, and engaging design. Modern consumers, both parents and B2B clients such as rental services and theme parks, demand products that not only provide entertainment but also adhere to stringent safety standards and offer long-term reliability. This comprehensive overview delves into the intricate world of manufacturing these sophisticated toys, from initial concept to final deployment.

The demand for robust and feature-rich children's ATVs continues to grow, driven by factors like technological advancements, enhanced safety features, and a greater emphasis on outdoor play. Manufacturers in this domain are constantly innovating to meet these evolving expectations, leveraging advanced materials and precision engineering to create products that are both fun and fundamentally safe.

Current Industry Trends and Market Dynamics

The sector for children's electric vehicles is marked by several key trends. Firstly, there is a persistent drive towards enhanced safety features, including parental remote control systems, automatic braking, and speed governors. Secondly, battery technology is continuously improving, offering longer run times and faster charging cycles, critical for both residential and commercial applications. Lithium-ion batteries, for example, are increasingly replacing traditional lead-acid batteries due to their superior energy density and lifespan. Thirdly, connectivity and smart features, such as Bluetooth music players and integrated diagnostic systems, are becoming more common, elevating the user experience.

Sustainability is also emerging as a significant trend. Reputable powered ride-on toys for kids - atvs manufacturers are exploring eco-friendly materials and energy-efficient manufacturing processes to minimize their environmental footprint. This includes using recycled plastics where appropriate and designing products for longevity and repairability. The global market for ride-on toys is projected to grow significantly, driven by increasing disposable incomes and a rising demand for innovative recreational products for children.

The Manufacturing Process: Precision and Quality Assurance

The production of high-quality powered ride-on toys, especially ATVs, is a multi-stage process that requires meticulous attention to detail and adherence to strict engineering standards. As experienced powered ride-on toys for kids - atvs factories, our process integrates cutting-edge technology with rigorous quality control at every step.

Process Flow Schematic:

1. Design & Prototyping

CAD modeling, 3D printing, ergonomic analysis, safety feature integration.

2. Material Sourcing & Preparation

High-grade PP plastic for body, durable steel for chassis, UL-certified electronics.

3. Component Fabrication

Plastic injection molding (casting), metal stamping/welding (forging), PCB assembly.

4. Assembly

Motor, gearbox, battery, wiring, body panels, wheels, steering integration.

5. Quality Control & Testing

Performance, safety (impact, stability), electrical, battery, load capacity tests.

6. Packaging & Logistics

Secure packaging, compliance with shipping regulations.

Product materials typically include high-impact resistant polypropylene (PP) or ABS plastics for the bodywork, ensuring both aesthetics and structural integrity. Chassis components are often constructed from robust steel alloys, treated for corrosion resistance to guarantee a long service life, even in outdoor environments. Electronic components, including motors, control boards, and wiring harnesses, are selected for their reliability and compliance with international electrical safety standards.

Manufacturing processes involve advanced plastic injection molding for precise body panel formation, CNC machining for critical metal components ensuring tight tolerances, and automated assembly lines for efficiency and consistency. Testing standards are rigorously applied throughout, including ISO 9001 for quality management, ASTM F963 for toy safety in the US, EN 71 for European markets, and CE marking. These certifications ensure that every product leaving our facility, as a dedicated toddler electric atvs manufacturer, meets global safety and quality benchmarks.

Technical Specifications and Advantages

Our products, as offered by a leading powered ride-on toys for kids - atvs supplier, are engineered for superior performance and safety. Key technical advantages include advanced motor and battery systems, durable construction, and intelligent control interfaces.

Typical Specifications for a Powered Ride-On ATV:

| Parameter | Specification |

|---|---|

| Motor Type | 12V/24V DC Electric (2x 35W - 4x 45W) |

| Battery Capacity | 12V 7Ah - 14Ah Lead-Acid / 12V 10Ah Lithium-Ion |

| Max Speed | 3-8 km/h (adjustable with speed modes) |

| Load Capacity | Up to 30 kg (66 lbs) for single rider |

| Material (Body) | High-Density Polypropylene (HDPE) or ABS Plastic |

| Material (Chassis) | Reinforced Steel Frame |

| Tire Type | EVA (Ethylene-vinyl acetate) Foam or Pneumatic Rubber |

| Charging Time | 8-12 hours for full charge |

| Run Time | 1-2 hours (dependent on terrain and load) |

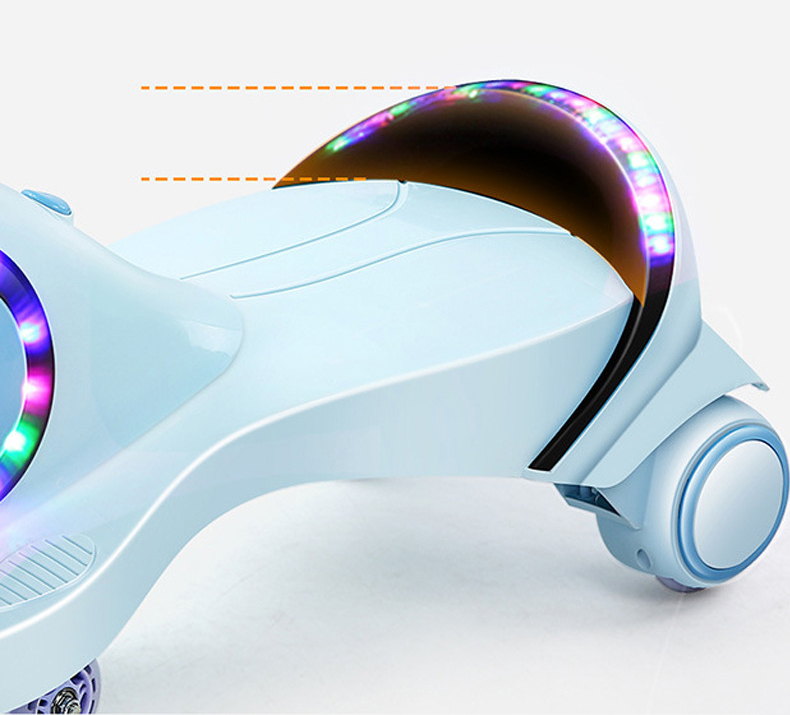

| Safety Features | Parental Remote Control, Soft Start, Seat Belt, LED Lights |

These specifications translate into tangible advantages for end-users and B2B clients. For instance, the use of robust materials ensures corrosion resistance and high impact tolerance, making the ATVs suitable for varied environments. Energy-saving designs in motor and gearbox configurations maximize battery life, reducing operational costs for rental businesses. Furthermore, the emphasis on safety, through features like soft-start acceleration and reliable braking systems, provides peace of mind. Our ATVs are built to provide an engaging and secure riding experience for children, making them a preferred choice among toddler electric atvs factories.

Application Scenarios and Industry Use

Powered ride-on toys for kids - atvs manufacturers cater to a broad spectrum of application scenarios, beyond just individual home use. These vehicles are ideal for:

- Recreational Parks & Theme Parks: Offering dedicated children's driving zones where durability, safety, and ease of maintenance are paramount.

- Family Entertainment Centers (FECs): Providing a popular attraction that draws families and encourages repeat visits.

- Rental Businesses: A robust fleet of ATVs can generate significant revenue, requiring products built for continuous, heavy-duty use.

- Educational Institutions & Nurseries: Integrating ride-on toys into learning environments to develop motor skills and coordination in a safe, controlled manner.

- Residential Use: Providing endless outdoor fun for children in backyards or community spaces.

In these diverse settings, the advantages of well-engineered children's ATVs become clear. For example, in a high-traffic rental scenario, the corrosion resistance of the steel chassis and the robust nature of the plastic body panels ensure minimal downtime due to wear and tear. The energy-saving features of the battery and motor system contribute to lower operational costs, as vehicles can run longer on a single charge and require fewer charging cycles over their lifespan.

Vendor Comparison: Choosing the Right Partner

Selecting a reliable toddler electric atvs manufacturer or supplier is paramount for B2B clients. Factors to consider extend beyond mere price points to encompass long-term value, safety, and support.

Key Factors for Vendor Comparison:

| Feature/Criterion | Leading Manufacturer (e.g., Us) | Standard Manufacturer |

|---|---|---|

| Certifications | ISO 9001, ASTM F963, EN 71, CE, RoHS, CPSIA | CE, perhaps limited regional certs |

| Material Quality | Virgin HDPE/ABS, Reinforced Steel, UL-certified electronics | Recycled plastics, thinner steel, generic electronics |

| Safety Features | Parental RC with emergency stop, soft-start, adjustable speed, seat belts, LED lights, overload protection | Basic RC, fixed speed, no soft-start, minimal safety tech |

| Battery Life/Technology | High-capacity Lead-Acid or Lithium-Ion with BMS, 300+ cycles | Standard Lead-Acid, 150-200 cycles, no BMS |

| Customization Options | OEM/ODM, branding, color, feature integration (e.g., specific music, display) | Limited branding, standard models only |

| Warranty & Support | Comprehensive 1-2 year warranty, readily available spare parts, dedicated tech support | Limited 6-month warranty, sparse spare parts availability |

Our commitment as a leading powered ride-on toys for kids - atvs factory extends to providing unparalleled quality, technical expertise, and customer support. With years of experience and a strong portfolio of client partnerships, we stand by the superior performance and longevity of our products.

Customized Solutions and OEM/ODM Capabilities

Recognizing the diverse needs of our B2B partners, we offer extensive customized solutions, including OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services. Whether it's a unique color scheme, custom branding, specific feature integration (e.g., advanced parental controls, localized audio content), or a completely new product design, our engineering team is equipped to bring your vision to life.

Our capabilities extend from concept development and detailed CAD design to mold fabrication, prototyping, and mass production. We work closely with clients to ensure that all specific requirements are met, adhering to critical safety and performance standards. This flexibility makes us a preferred partner for businesses looking to differentiate their offerings in the competitive market for toddler electric atvs factories.

Application Case Studies and Customer Experience

Our track record as a prominent powered ride-on toys for kids - atvs manufacturer includes numerous successful deployments across various industries.

Case Study 1: Large-Scale Theme Park Integration

A major theme park in Southeast Asia sought to revitalize its children's ride section with a fleet of durable, safe, and visually appealing electric ATVs. We supplied over 100 customized units, featuring reinforced chassis, extended battery life, and unique park-specific branding. Customer feedback highlighted the exceptional durability, with vehicles withstanding continuous daily operation for over two years with minimal maintenance. The integrated safety features, particularly the remote emergency stop, were highly praised by park operators, ensuring optimal safety for young riders. This significantly boosted park attendance in the children's area and led to repeat orders.

Case Study 2: National Toy Retailer's Exclusive Line

A national toy retail chain partnered with us to develop an exclusive line of toddler electric ATVs. The challenge was to create a product that stood out in a saturated market while meeting strict consumer safety and quality expectations. Through our ODM services, we designed a new model featuring innovative suspension, an interactive dashboard, and a unique color palette. The product line became a top seller, praised for its advanced features, robust build, and exceptional value for money. The retailer noted a significant increase in customer satisfaction ratings and brand loyalty due to the quality and unique appeal of the ATVs.

Trustworthiness and Support: Your Reliable Partner

As a trusted powered ride-on toys for kids - atvs manufacturer, our commitment extends beyond product delivery to comprehensive customer support and transparency in operations.

Frequently Asked Questions (FAQ)

Q: What safety certifications do your ATVs hold?

A: All our powered ride-on ATVs comply with international safety standards including ASTM F963 (USA), EN 71 (Europe), CE, RoHS, and CPSIA requirements. Each product undergoes rigorous testing for material safety, structural integrity, and electrical compliance.

Q: Can your products be customized for specific branding or features?

A: Yes, we offer extensive OEM/ODM services. Clients can request custom branding, color schemes, specific electronic features like advanced parental remote controls, unique sound effects, or even entirely new designs based on their specifications.

Q: What is the typical lead time for a bulk order?

A: Lead times vary depending on order quantity and customization complexity. For standard models, typical lead time is 25-35 days after deposit and confirmation of order details. Customized orders may range from 45-60 days due to design, tooling, and prototyping stages.

Q: What kind of warranty and after-sales support do you offer?

A: We provide a standard 1-year warranty on major components (motor, gearbox, PCB) and 6 months on batteries from the date of purchase. Our dedicated after-sales team offers technical support, troubleshooting, and readily available spare parts to ensure long-term product satisfaction and operational continuity for our B2B partners.

Lead Time & Fulfillment

Our streamlined supply chain and efficient manufacturing processes allow for competitive lead times. We maintain robust inventory levels for critical components and employ flexible production scheduling to accommodate urgent orders while ensuring consistent quality. Detailed fulfillment tracking and logistics support are provided from factory to destination, ensuring timely and secure delivery.

Warranty Commitments

Our warranty policy is designed to instill confidence in our products and partnership. We stand behind the quality and durability of our powered ride-on ATVs, offering comprehensive coverage against manufacturing defects. Detailed terms and conditions are provided with every order, ensuring full transparency.

Customer Support

Our dedicated B2B customer support team is available to assist with technical inquiries, spare parts orders, and general support. We believe in building long-term relationships through proactive communication and responsive service, empowering our partners to maximize their investment in our products.

Conclusion

The selection of a reliable powered ride-on toys for kids - atvs manufacturer is a strategic decision for any business operating in the children's recreational vehicle market. With a steadfast commitment to quality, safety, innovation, and comprehensive customer support, we stand as a premier partner for B2B clients globally. Our advanced manufacturing processes, adherence to stringent international standards, and capacity for customized solutions ensure that we deliver not just products, but complete solutions that drive success for our partners.

From material sourcing to final product delivery, every step is optimized for performance, durability, and most importantly, the safety and enjoyment of children. Partner with us to elevate your product offerings and ensure a superior experience for your customers.

Citations

- International Organization for Standardization. ISO 9001:2015 - Quality management systems - Requirements.

- ASTM International. ASTM F963 - Standard Consumer Safety Specification for Toy Safety.

- European Committee for Standardization. EN 71 - Safety of toys.

- Consumers Product Safety Commission. CPSIA - Consumer Product Safety Improvement Act.

- Research and Markets. Children's Ride-on Toy Market - Global Outlook and Forecast 2023-2028.

-

Powered Ride-On ATVs for Kids | ATVs Manufacturer & SupplierNewsAug.27,2025

-

Powered Ride-On Toys for Kids - ATVs | Manufacturer & SupplierNewsAug.26,2025

-

Powered Ride-On Toys for Kids - ATVs Manufacturer | Safe & DurableNewsAug.25,2025

-

Powered Ride-On ATVs for Kids - Direct Manufacturer & FactoryNewsAug.24,2025

-

Safe Girl Baby Walkers: 3-in-1 Fun & Support for Her First StepsNewsAug.23,2025

-

Kids' Powered Ride-On ATVs: Quality Manufacturer & SupplierNewsAug.22,2025